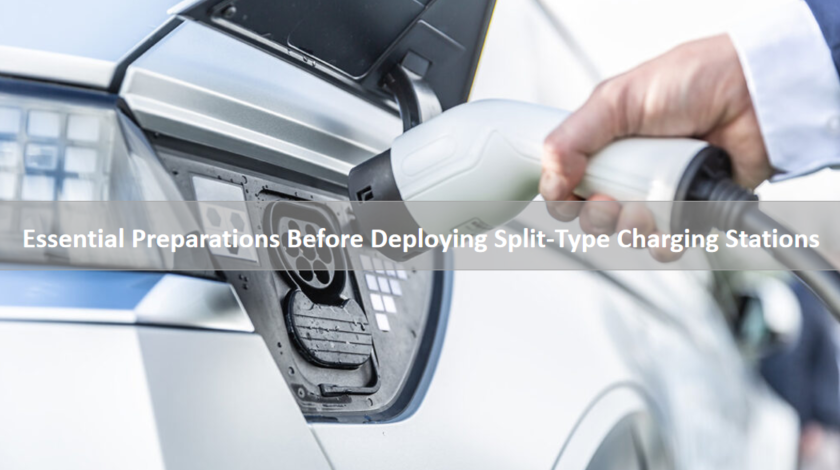

For newcomers entering the clean energy and new energy vehicle charging industry, split-type charging stations (also known as "one-to-multiple" charging systems) are an ideal choice for building small to medium-sized charging stations due to their high flexibility and excellent return on investment. However, their technical complexity and high demands for preliminary planning mean that thorough preparation is the cornerstone of project success and avoiding pitfalls. This article provides a comprehensive checklist for deploying split-type charging stations from scratch, helping you gain clarity and advance your project step by step.

1. Introduction to Split-Type Charging Stations

A split-type charging station is an intelligent charging system based on a "centralized power supply, distributed charging" architecture. Its core consists of a centralized Power Distribution Cabinet (host) and multiple dispersed Charging Terminals (slaves/gun sockets).

- Working Principle: The power cabinet integrates all core charging modules and an intelligent control system. It functions like a "power pool," dynamically and intelligently allocating the total power to each charging terminal based on the connected vehicles' battery demands and charging priorities. For example, a 360kW power cabinet can allocate 90kW to each of four vehicles simultaneously or prioritize allocating 240kW to one vehicle while distributing the remaining power to others.

- Core Value:

- Efficient Utilization of Grid Capacity: Serves more vehicles without increasing total power, preventing waste.

- Lower Cost per Unit: As the number of terminals increases, the average investment per charging gun decreases significantly.

- Future Scalability: Initial deployment can start with fewer terminals; expansion later only requires adding terminals, protecting the initial investment.

- Centralized Intelligent Management: Operations, maintenance, upgrades, and monitoring are handled uniformly through the host, improving efficiency.

2. Typical Application Scenarios for Split-Type Charging Stations

Identifying your project's scenario is the first step in selecting the right technical solution:

- Public Fast-Charging Stations: Parking lots in urban core areas, transportation hubs, and commercial districts with high traffic flow, requiring efficient service for various vehicle models.

- Dedicated Operation Depots: Exclusive charging areas for ride-hailing fleets, logistics fleets, and bus terminals, where vehicles are concentrated and charging patterns are regular.

- Commercial Real Estate Supporting Facilities: Parking lots of large shopping malls, office parks, and hotels, offering value-added services to attract customers.

- Highway Service Areas: Requiring high reliability to handle holiday peak charging demands.

3. Detailed Preparation Checklist (A Seven-Step Guide)

(1) Site Survey: Everything Starts On-Site

This is the most critical step, determining the project's physical foundation and cost structure.

- Parking Space Resources: Confirm the number, location, dimensions of available spaces, and property/lease terms (recommended: over 5 years).

- Electrical Capacity: Locate the distribution room and verify the remaining capacity (in kVA) of the existing transformer. This is the hard constraint determining the total power limit of the charging station. A professional electrician or electrical designer must take on-site measurements.

- Cable Routing Path: Plan the cable trench or bridge path from the distribution room to the power cabinet installation point and then to each charging terminal. Longer distances mean higher cable costs.

- Civil Engineering Conditions: Confirm the installation location for the power cabinet (large volume), such as ground foundation or wall mounting, and whether waterproofing, sun protection, or collision protection measures are needed.

(2) Grid Filing: Obtain the "Birth Permit"

A formal electricity application must be submitted to the local power supply company before purchasing equipment.

- Prepare Documents: Typically includes business credentials, site proof, and an electricity plan (containing total power, equipment list, load calculation, etc.).

- Key Communication Points: Clarify whether capacity expansion (increasing transformer capacity) is needed, along with associated costs and timelines. Understand local electricity pricing policies for charging stations (e.g., whether industrial electricity rates apply, peak/off-peak pricing).

- Obtain Approval: Secure the Power Supply Scheme Reply from the utility company, which serves as the basis for subsequent electrical design and construction.

(3) Procure Grid-Side Equipment: Build a Solid Electrical Foundation

Procure and install front-end electrical equipment as required by the utility company.

- Common Equipment: Includes high-voltage switchgear, transformers (if capacity expansion is needed), low-voltage distribution cabinets, metering boxes, etc. This is often referred to as the "external line project" or "grid connection project."

- Responsible Party: Equipment procurement and installation may be handled by utility-designated or recommended contractors, or by the owner hiring a qualified electrical engineering company. This must be clarified in advance.

(4) Consult Charging Station Suppliers: Define the Technical Solution

With site survey data and the grid reply in hand, consult 3-5 mainstream charging equipment suppliers for technical proposals.

- Requirements Communication: Provide a parking lot layout, electrical capacity, target vehicle types (e.g., focused on taxis or private cars), and request suppliers to provide a preliminary technical proposal and configuration list.

- Key Inquiries:

- Recommendations for total power cabinet capacity and terminal quantity configuration.

- Whether the system supports advanced features like intelligent power allocation, V2G, and orderly charging.

- Equipment interface standards, communication protocols, and platform integration capabilities.

- Warranty period, maintenance response speed, and service network.

- Site Visits: Essential to visit the supplier's completed similar projects to observe equipment operation and operational data.

(5) Calculate Return on Investment (ROI): Run the Numbers

Conduct rigorous financial analysis before finalizing the solution.

- Investment Costs: Include all expenses: equipment procurement (charging stations, cables), grid-side engineering, civil construction, software platform, installation, and commissioning.

- Operational Revenue: Estimate based on local charging service fee levels, projected daily charging volume (utilization rate), and electricity price differentials.

- Operational Costs: Include electricity fees, equipment maintenance, platform service fees, site rental, and management labor.

- Key Metrics: Calculate Payback Period, Internal Rate of Return (IRR), and Break-Even Point. A healthy public charging station project typically has a payback period of 3-5 years.

(6) Select an Installer: Find a Reliable "Construction Team"

Installing charging stations requires coordination among electrical, network, and civil engineering trades.

- Selection Methods: Can opt for a "turnkey" project service from the equipment supplier or hire an experienced charging station installation specialist separately.

- Qualification Review: Verify the installer's qualifications, such as power facility installation/repair licenses and safety production permits.

- Review Past Projects: Examine completed projects of similar scale and understand their post-sales response capability.

- Clear Contract: Define the scope of work, construction standards, timeline, warranty period, and responsibilities of both parties clearly in the contract.

(7) Procure/Install/Test Charging Stations: Execution and Implementation

After completing the above steps, move into the implementation phase.

- Sign Procurement Contract: Finalize the contract with the selected supplier, specifying equipment specifications, price, delivery time, payment terms, and training clauses.

- Coordinate Installation: Ensure close collaboration among the equipment supplier, installer, and grid-side contractor for orderly power cabinet placement, cable laying, terminal installation, and network connectivity.

- System Commissioning and Testing: Conduct comprehensive system integration testing post-installation. Tests should include: charging functionality, power allocation strategy, payment process, platform data upload, and safety protections (e.g., emergency stop, leakage protection).

- Acceptance and Handover: Organize formal acceptance with all parties, confirm normal equipment operation, receive all technical documents and operation manuals, and train operational staff.

4. Conclusion

For newcomers to the clean energy industry, deploying split-type charging stations is a systematic engineering project. "Planning First" is far superior to "Learning by Doing." The key to success lies in delegating professional tasks to professionals while maintaining a clear overview and control of the project's critical milestones.

Strictly follow this seven-step preparation checklist: Start with a site survey to understand your baseline, proceed to grid filing for permits; from technical consultation to define the solution, to precise ROI calculation for risk control; and finally, select reliable partners for high-quality implementation.

With patience and meticulous attention to each step of research and decision-making, you can minimize risks and ensure your first charging infrastructure project is not only successfully built but also becomes a stable, profitable, and valuable long-term asset. Wishing you great success on your clean energy journey!