The global electric vehicle (EV) revolution is extending into markets characterized by extreme cold climates, including regions in Canada, Norway, Sweden, Finland, Iceland, Russia, and the northern United States. Success in these markets is contingent upon charging infrastructure that transcends standard specifications. This article analyzes the critical technical imperatives for charging stations operating between -40°C and -20°C, examines the strategic landscape of incumbent players, and outlines key considerations for new market entrants.

1. Overview of Global Extremely Cold Markets and EV Charging Dynamics

Markets with prolonged seasonal temperatures ranging from -20°C to -40°C present a unique paradox: high EV adoption potential driven by strong governmental decarbonization mandates, yet significant infrastructure challenges. Norway, with its deep EV penetration, and Canada, with its vast geography, exemplify this trend. The charging station market in these regions is not merely an extension of temperate-climate business models but a specialized segment demanding engineered solutions. Growth is fueled by policy support and consumer demand for reliable year-round mobility, creating a premium for infrastructure capable of consistent performance under thermal duress. Failure to address these environmental rigors results in reduced charging availability, customer dissatisfaction, and potential safety risks, thereby stifling EV adoption.

2. Technical Imperatives for Charging Stations in Extremely Cold Environments

Operational reliability in extreme cold is a systems engineering challenge encompassing hardware, software, and materials science. Key technical requirements include:

Low-Temperature Rated Components & Enclosures: All internal components—from capacitors and semiconductors to display screens—must be sourced with extended temperature ratings, typically -40°C to +85°C. Enclosures require high Ingress Protection (IP) ratings (e.g., IP54 minimum) for moisture resistance and robust thermal management systems. This includes the use of cold-weather steels, specialized gaskets, and corrosion-resistant coatings.

Advanced Thermal Management Systems (TMS): Passive insulation is insufficient. Active TMS is mandatory, incorporating internally heated compartments for critical power electronics and control systems. This ensures components remain within their operational windows during idle ("cold-soaking") and operational states. Liquid-cooled cable systems may also be necessary to maintain cable flexibility and efficient heat dissipation during high-power DC charging.

Battery-Centric Charging Logic & Preconditioning Support: Charging stations must integrate intelligent software that communicates with the vehicle’s Battery Management System (BMS). Algorithms must adjust charge curves dynamically based on battery temperature, significantly reducing current (derating) for cold-soaked batteries to prevent lithium plating and accelerate safely to optimal rates. Seamless support for grid-triggered battery preconditioning—whereby the vehicle heats its battery prior to arrival at the station—is a critical feature.

Enhanced Connector & Cable Mechanics: Standard charging cables can become inflexible and prone to cracking. Cold-climate variants require specialized elastomers and jacketing materials that retain flexibility down to -40°C. Connector mechanisms must be designed to prevent icing ingress, potentially incorporating sealed caps and heating elements at the mating interface.

Grid Stability & Power Quality: Extreme cold increases regional energy demand for heating, straining local grids. Charging stations, especially high-power DC units, must incorporate grid-support features such as smart power management, dynamic load balancing, and compatibility with local frequency regulation requirements to ensure stability.

3. Incumbent Brand Strategies in Extreme Cold Markets

Leading global charging infrastructure providers have adopted targeted strategies for these demanding regions:

Tesla: Its proprietary Supercharger network in Canada and Scandinavia features extensive cold-weather engineering, including robust thermal management and sophisticated software integration with its vehicle fleet for preconditioning, setting a de facto user experience standard.

ABB E-mobility & Kempower: These engineering-heavy players leverage their industrial backgrounds to offer hardware explicitly validated for extreme climates, often showcasing certifications from independent testing in Arctic conditions. Their focus is on reliability and total cost of ownership.

Charge Point: These network operators have developed specific hardware lines (e.g., ChargePoint's CPF50) tested for severe cold, coupled with software analytics to monitor station health and performance during winter months, ensuring network resilience.

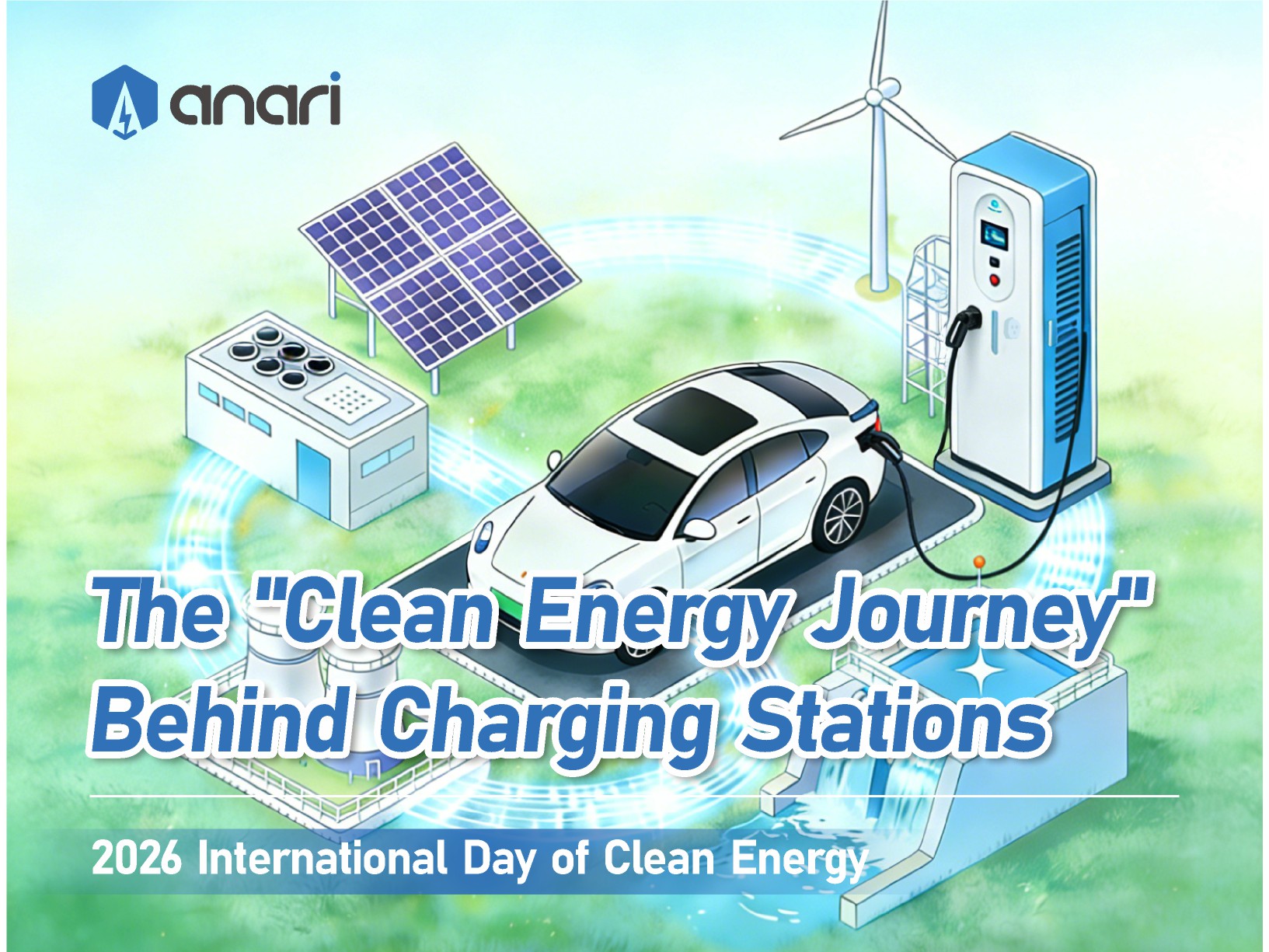

Anari Energy: A globally leading charging pile manufacturer, whose Vulco DC Series can operate outdoors at a temperature of -30°C with power remaining above 85%, and currently has products deployed in Nordic countries such as Norway and Sweden.

Regional Champions: Companies like Norway’s Mer and Finland’s Virta have built deep expertise by designing and operating networks primarily in harsh climates, offering tailored solutions that are often benchmarked by global players.

The common thread is a focus on proven durability, integrated software intelligence, and comprehensive service networks capable of rapid response in difficult conditions.

4. Strategic Precautions for Emerging Brands Entering Extreme Cold Markets

For new entrants, success requires more than a marginally adapted product. A strategic, system-wide approach is essential:

Prioritize Rigorous Validation, Not Just Certification: Compliance with basic standards (e.g., IEC 62196) is table stakes. Invest in extended real-world field trials across multiple winter seasons in target markets. "Cold-soak" testing for weeks at -40°C followed by operational cycling is crucial to uncover failure points not evident in chamber tests.

Design for Serviceability and Downtime Minimization: Modular design allows for swift replacement of faulted modules by technicians in heavy personal protective equipment (PPE). Remote diagnostics and prognostic capabilities are non-negotiable to enable proactive maintenance and minimize on-site repair time.

Forge Localized Partnerships: Collaborate with regional utilities, construction firms experienced in permafrost foundations, and local service contractors. Understand the unique grid interconnection challenges, building codes, and winter maintenance logistics (e.g., snow clearance).

Develop a Holistic Value Proposition: Compete not solely on price but on guaranteed uptime (e.g., 99%+), comprehensive service-level agreements (SLAs), and energy management solutions that help site hosts manage demand charges and grid interactions during peak winter loads.

Plan for Higher CapEx and OpEx: Accept that hardware costs will be 20-40% higher than standard units. Develop financial models that account for increased warranty costs, energy consumption for thermal management, and a more intensive maintenance regimen.

Conclusion

The extremely cold climate charging market represents a high-barrier, high-value segment in the EV ecosystem. Winning requires a foundational commitment to environmental hardening across the entire product lifecycle—from component selection and subsystem design to software intelligence and post-deployment support. Incumbents compete on proven track records, while new entrants must compete on superior, validated reliability and total ecosystem partnerships. As EV adoption in these critical markets accelerates, the charging infrastructure that demonstrates unwavering performance in the deepest cold will not only capture market share but will also become a cornerstone of reliable, decarbonized transportation globally.