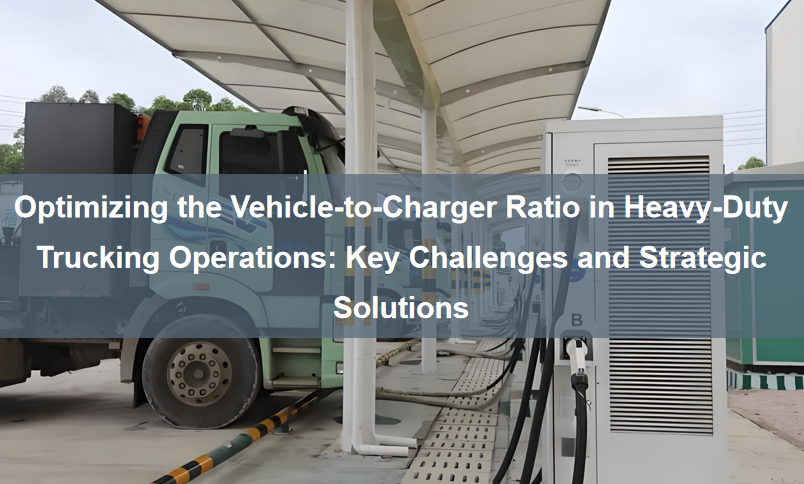

On the path toward the electrification of heavy-duty trucks, we recognize that the central focus extends beyond vehicle range alone to encompass the continuous, efficient, and reliable operation of the entire fleet. As the "energy heart" of the operation, the strategic planning of charging infrastructure is a critical determinant of both operational efficiency and cost. Among the core planning metrics, the "vehicle-to-charger ratio" is paramount. It is not merely a simple numerical ratio of chargers to vehicles, but rather a key indicator for assessing a fleet's operational potential under the dual constraints of fixed time and fixed power.

I. Core Challenge: The Stringent Demands of the Vehicle-to-Charger Ratio in Heavy-Duty Trucking

Unlike passenger vehicles, charging for heavy-duty trucks is subject to two unavoidable rigid constraints:

1. Hard Time Window Constraint:

Driven by high electricity costs, fleet charging must be concentrated during nightly off-peak periods (typically limited to 8 hours). This necessitates the completion of all energy replenishment within this finite "charging window." Any vehicle queuing or slow charging will inevitably result in a portion of the fleet being unable to depart fully charged the following day, directly causing operational disruptions and economic losses.

2. Station Power Cap Constraint:

The total power capacity (high-voltage grid connection) available to a charging station is fixed and costly. While selecting higher-power individual chargers reduces per-charge time, it rapidly depletes the total available station capacity, severely limiting the number of chargers that can be installed. This creates a bottleneck: even with high-power chargers, an insufficient quantity will lead to fleet charging queues.

These twin challenges collectively dictate that a charging station must achieve maximum efficiency in "serving the highest number of vehicles within limited time and power."

II. Strategic Choice: High-Power Single Chargers vs. Intelligent Group Charging

In response to these challenges, two primary technological pathways have emerged within the industry, yielding significantly different vehicle-to-charger ratios and operational outcomes.

A. Single-Station High-Power Solution – The "Single-Lane" Model

- Model Description: Utilizes independent high-power charging piles, with each pile serving one vehicle fixedly and independently.

- Vehicle-to-Charger Ratio Reality: Within an 8-hour window, considering heavy-truck charging cycles, a single charger can theoretically serve a maximum ratio of approximately 1:4.

- Inherent Risk: This model is highly susceptible to grid capacity constraints, often resulting in an insufficient number of installed chargers. Should any vehicle experience charging delays, it triggers a "domino effect," disrupting the charging schedule for all subsequent vehicles and introducing significant operational risk.

B. Split-Type Solution – The "Intelligent Interchange" Model

- Model Description: This is our company's core recommended solution. The system aggregates the station's total power into a flexible "power pool," dynamically allocating power to each vehicle based on real-time state-of-charge and demand via intelligent scheduling algorithms.

- Optimized Vehicle-to-Charger Ratio: Intelligent "peak-shifting" and "peak-shaving/valley-filling" mechanisms dramatically improve total power utilization efficiency. Under the same total power capacity, vehicle-to-charger ratios of 1:5.5 or higher are achievable.

- Core Advantage: Guaranteed Non-Overload. The system intelligently prevents all vehicles from charging at peak power simultaneously, ensuring all vehicles are fully charged within the planned time and power constraints. This provides predictable, anxiety-free operational assurance.

III. Our Recommendation: Embrace the Split-Type Solution for a Deterministic Operational Future

For heavy-duty truck fleets pursuing large-scale, high-efficiency operations, optimizing the vehicle-to-charger ratio is fundamentally about optimizing investment efficiency.

Adopting the group charging technical solution translates to:

- Higher Asset Utilization: Serve a larger fleet with the same power capacity, thereby reducing the charging infrastructure cost per vehicle.

- Stronger Operational Resilience: Intelligent scheduling mitigates chain reactions caused by single-point failures, resulting in more reliable charging plans.

- Clearer Return on Investment: A shift from a 1:4 to a 1:5.5 vehicle-to-charger ratio directly corresponds to a leap in station service capacity and potential revenue growth.

In the era of heavy-truck electrification, charging infrastructure construction is a crucial strategic decision. The "vehicle-to-charger ratio" should not be viewed as a simple numeric metric, but rather as the top-level design parameter for fleet operational efficiency. We are confident that by adopting advanced group charging power pooling technology, we can help you break through bottlenecks and maximize fleet operational efficiency within defined constraints, steering decisively towards a profitable and sustainable future.